Conventional Network

Subtítulo sit amet consectetur adipiscing elit.

- A team of highly experienced and specialised employees.

- State-of-the-art technology to meet the requirements of transport operators.

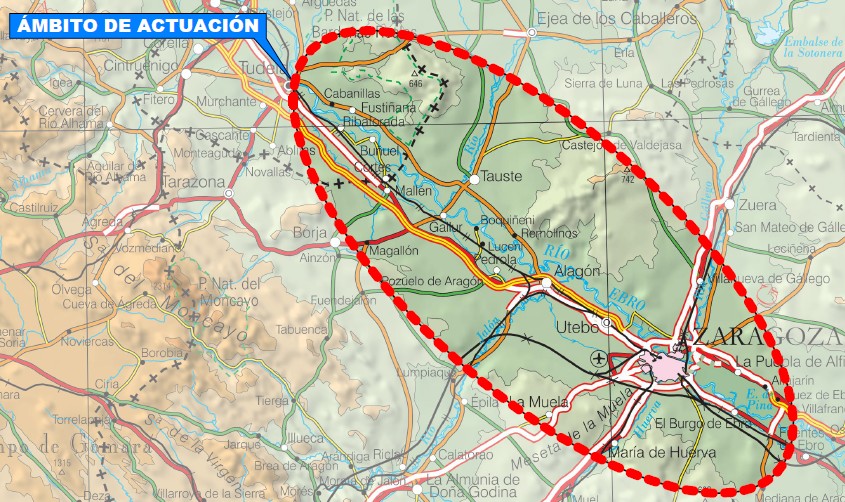

- Machinery, vehicles and maintenance bases tailored to the railway network's productive needs across Spain.

Infrastructure

Railway infrastructure is the base that supports the so-called “rail road”. It underlies the tracks, as well as the signalling, electrification and telecommunications installations that make it possible for trains to circulate.

km of track we maintain

equivalent to a total length of 497 km.

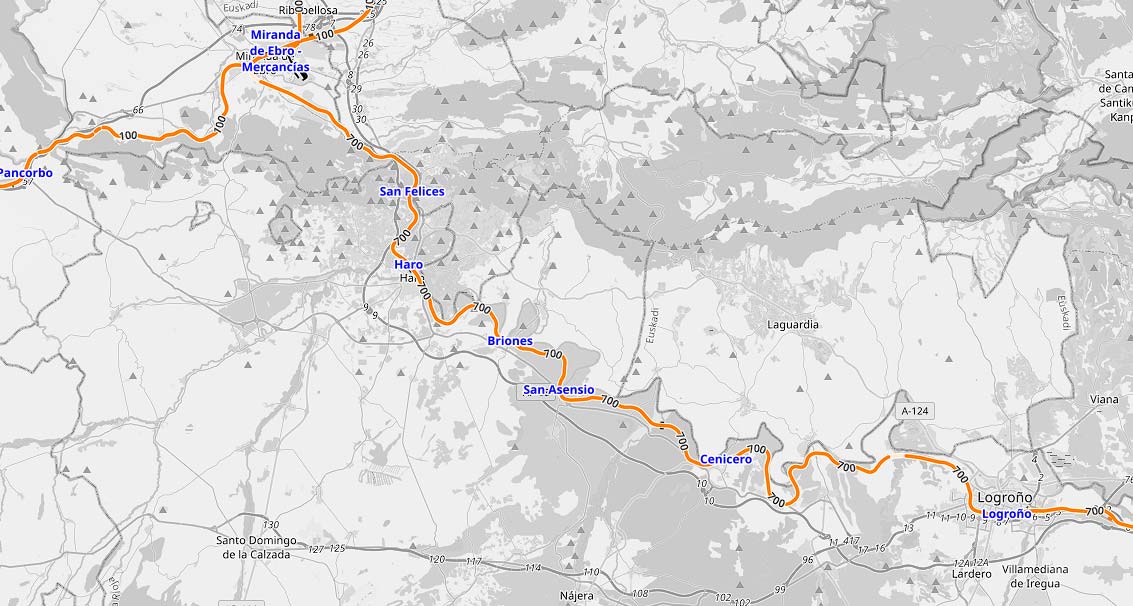

with a length of 135.15 km.

Load tests performed annually

More about the infrastructure

Track

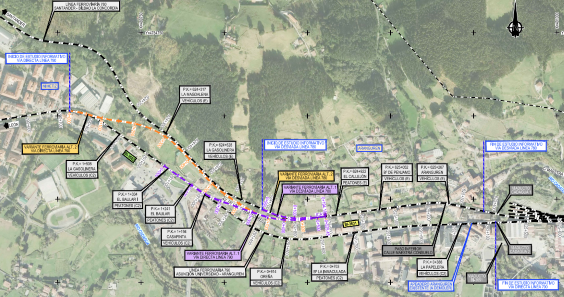

Actions to be highlighted

Signalling

.

Electrification

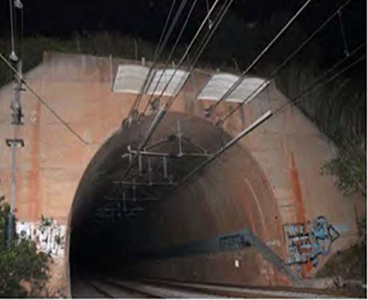

Electrification work is carried out at electricity substations and the overhead contact line. The overhead contact line, or"catenary", supplies electricity to the train.

All maintenance of these facilities is scheduled. Precise actions are coordinated with our territorial organisation, which also performs regular reviews in the high voltage line that feed our substations.

We have added to the features of our substations by putting in place a distributed control system and standardising new rectifiers, transformers, diodes and fuses.

Overhead contact line

High voltage line

Electrical substations

Installed capacity

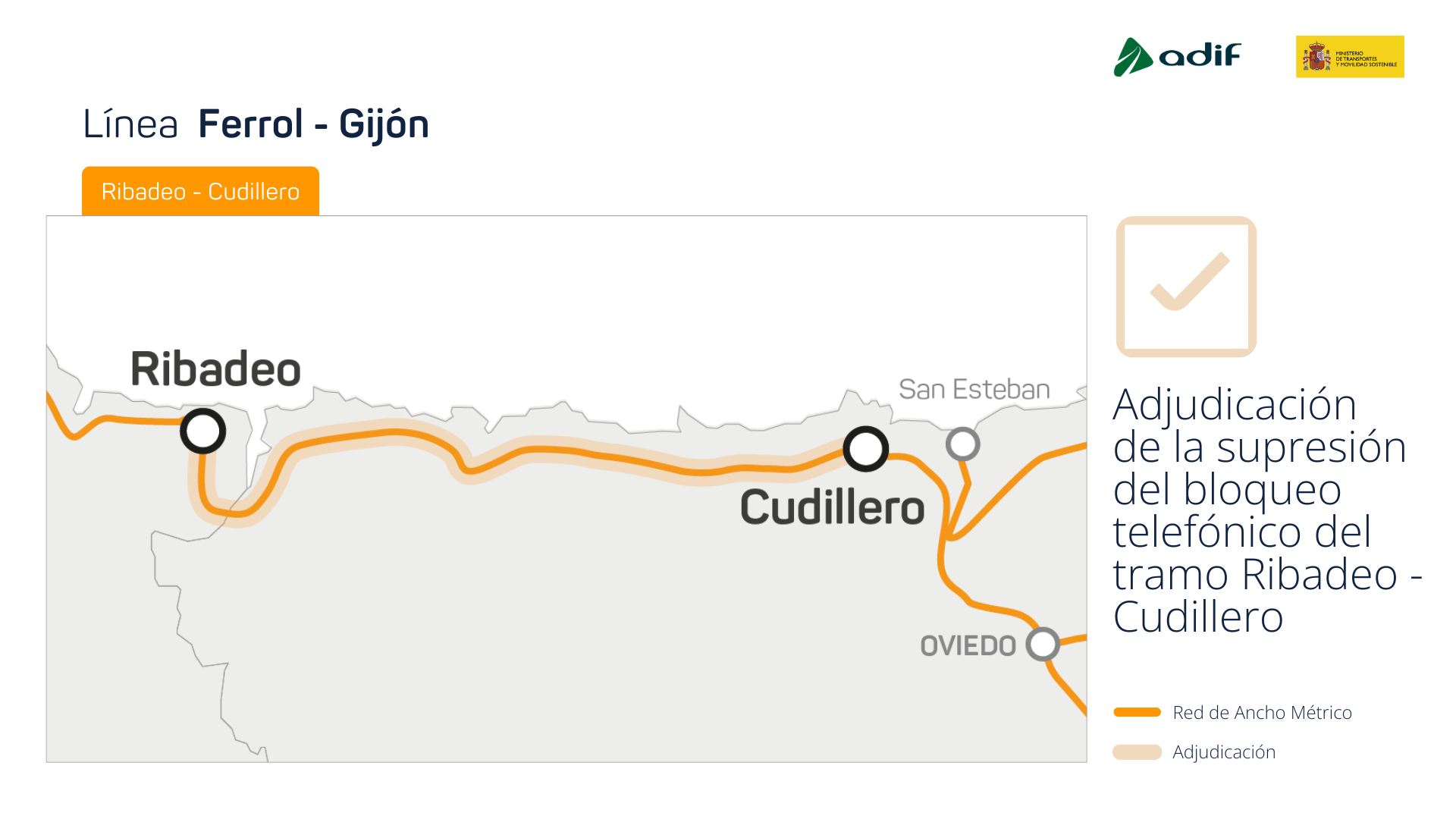

Telecommunications

Rail transport requires the exchange of a massive volume of data due to its myriad activities and operational and management complexity. Moreover, the dispersion of the various work centres requires differentiated telephony telecommunication services for management, data and operations, e.g. traffic control telephony, remote controls, signalling, public address system. These services and their different management and control systems are integrated into an exclusive telecommunications network.

Production processes

The processes are divided up into three main categories relating to the technical specialties of infrastructure, tracks, signalling, electrification and telecommunications.

Activities

Quality and participation

Staff in the Conventional line are heavily involved in the the Annual Quality Participation Contest, where they submit initiatives for operational and management improvements through Initiative and Improvement Groups (IIG) and Initiative and Improvement Teams (IIT).

Systematic production process organisation has given rise to a new profile of maintenance activities that increases facility availability and enhances inspection management, thereby reducing incidents.

Our Environmental Management System is based on the ISO 14001: 2004 standard. We developed a series of general and specific procedures for the various technical specialties, identifying the environmental aspects affected in each activity.

We have 28 waste management points distributed across Spain that provide service to all our operational areas. These waste management points contribute effectively and rationally to our commitment as an environmentally friendly organisation.

We have also developed a series of Environmental Best Practices centred on reducing electricity and water consumption and managing waste.

We obtained certification in accordance with the OHSAS 18001 standard in 2006 after assurance by AENOR that our occupational health and safety (OHS) management meets the requirements of that standard.

With this certification, considered the highest level of employee health and safety internationally, we easily exceed the minimum requirements of current legislation. Adif was the first European railway organisation to achieve certification according to this standard.

Level crossings

The number of level crossings has decreased considerably from approximately 10,000 in mid-1970s, while improved safety measures have been put in place in those still providing service.